How Photogrammetry Can Enhance Product Development and Research

Photogrammetry is a technique used to capture and combine measurements from photographs. These measurements are used to create detailed 3D models of objects. Photogrammetry has many uses, but one of the most common is in the field of product development and research. In this blog post, we’ll explore how photogrammetry can enhance your own product development and research process. We will explore how photogrammetry can help you streamline your process, reduce time spent on research and documentation, improve collaboration across teams, and even allow you to create new experiences for your customers—all while maintaining optimal security.

What is Photogrammetry?

Photogrammetry is the science of making measurements from photographs. A photogrammetric surveyor uses this method to take measurements from photographs. These measurements are used to create a 3D representation of a real-world subject.

Photogrammetry can be used to do accurate surveying as well as to create 3D models of objects. It is also used in many other fields like architecture, engineering, archaeology, robotics, film, and animation.

The word “photogrammetry” is made up of two Greek words, “photon”, which means light, and “metron”, which means measurement.

Light travels in straight lines. Instead of measuring the distance from a single point to an object and trying to find the intersection of those lines, photogrammetry uses light to form a 2D image of the object.

The photogrammetric process starts with the acquisition of images. Once you have your images, you need to use photogrammetric software to process them. This software will create a 3D model of your object.

Why Use Photogrammetry for Product Development?

As digital marketing continues to evolve, companies are increasingly turning to virtual reality and augmented reality to engage their customers and potential customers. Virtual and augmented reality is rapidly changing how we design and engineer products and will play a large role in the future of product development.

The primary reason for using photogrammetry for product development is that the technology results in high-quality 3D models. These detailed models can be used to create virtual and augmented realities. Combined with other technologies like AI and blockchain, photogrammetry makes it possible to automate many of the manual tasks associated with product development. With more automation, engineers and designers have more time to focus on innovation.

Benefits of Photogrammetry in Product Development and Research

Since photogrammetry relies on pictures as its source data, you can capture your data from a variety of different sources. You can use drones, satellites, robots, or even people with cameras. This flexibility allows you to capture data in any environment or situation. You can even use photogrammetry to recreate the inside of a customer’s home.

Because there is no need to manually record measurements, photogrammetry makes it faster and easier to create virtual or augmented reality. It will also reduce the margin of error significantly.

Create New Customer Experiences

Virtual and augmented realities built with photogrammetry give customers an immersive experience. These experiences are highly precise and accurate. Because these realities are created from pictures, they are also very realistic.

Companies can use photogrammetry to create lifelike customer experiences that are impossible to create with traditional methods like print, packaging, and websites.

For example, you might create a virtual reality for customers who want to try out a new couch before buying one. Or you might create an augmented reality that shows customers how their new car will look inside and outside.

Reduce time spent on documentation and research

With photogrammetry, you don’t have to record measurements manually. This reduces the margin of error and allows designers and engineers to spend less time on documentation. Photogrammetry also makes it easier to create 3D models of real-world objects. This makes it easier to research and design something before it is actually built.

For instance, before designing a new car, engineers use computer-aided design (CAD) software. But this software isn’t accurate enough to create a virtual reality or a lifelike model of the car. Using photogrammetry, engineers can create digital mock-ups of the cars with realistic materials and textures.

Conclusion

Photogrammetry is a powerful technology that can be used in a variety of industries for a variety of different uses. It can be used to create extremely accurate 3D representations of people, buildings, and even objects.

It can also be used to create lifelike virtual and augmented realities. And it can do this without the need for specialized equipment like cameras or other heavy machinery. All you need is a smartphone and the right software.

But that’s not all. Photogrammetry can also be used to create more streamlined product development processes. It can also be used to create new customer experiences and reduce the time spent on research.

Need unique photogrammetry services for your next project? Get an estimate below or check out our shop for pricing.

Digitization - Using Software to Duplicate Products

Updated: Jan 20, 2023

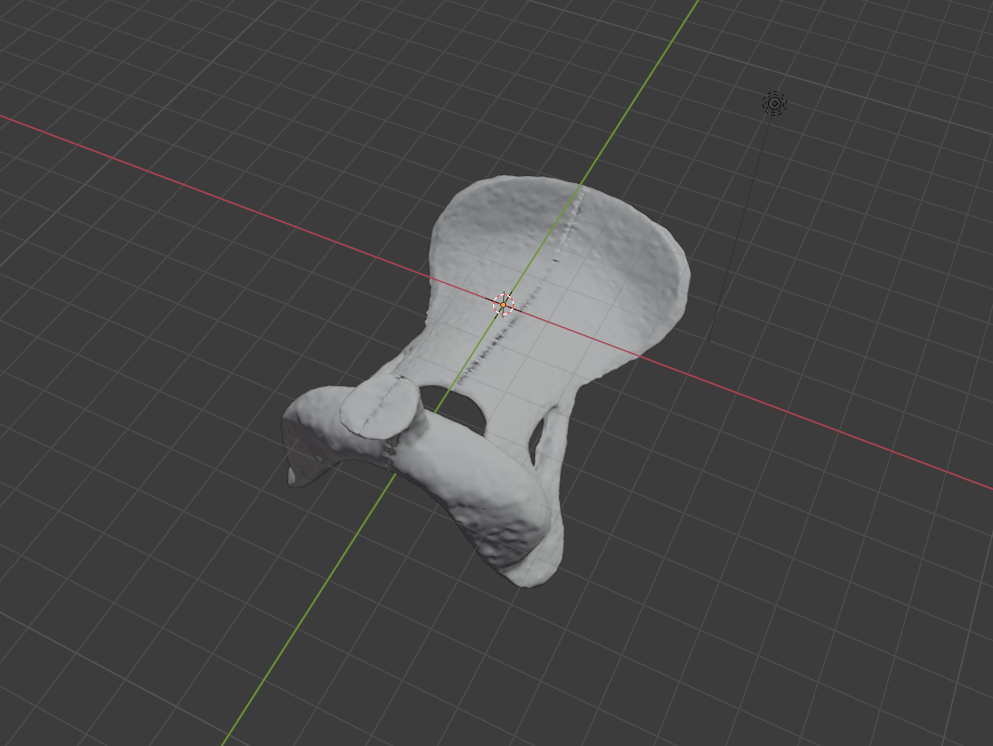

A client reached out to duplicate a master copy of a model they had. The complex horse saddle was an excellent test case for ALTAY to expand into secondary services for model reproduction. After a brief phone call, quote, and email exchange, the model maker mailed over the master saddle copy. After a couple of hours of tinkering and settling on our method, ALTAY was able to reproduce a 1:1 scale digital model of the saddle. After the digitization was completed, we printed a test and sent a photo of the print for a review.

Saddle Rendering after Digitization.

Saddle Print and Master.

Upon approval, ALTAY printed a duplicates of the saddle various scales so they can test out their new product line and verify its what they were looking for.

After sending back the first prints, we were asked to digitize 2 additional scale models for the client. These went well, with a few of the smaller digitizations that took longer than expected. We are excited to continue to add more products and refine the photogrammetry process to better serve the hobby model community.

In the end it ended up as a cost effective solution for their modeling needs and provided an easy method to manufacture their products at different scales.